Services

- Home

- Services

FIRE EXTINGUISHER

- AMC

- DESCRIPTION

- SCOPE OF WORKS

What is an AMC?

An Annual Maintenance Contract is a service agreement between a property owner and a

service provider for regular maintenance of fire extinguisher.

Purpose of AMC:

The purpose of an Annual Maintenance Contract (AMC) for fire extinguishers is to ensure they are regularly

inspected and maintained for reliability and compliance with safety regulations. It helps identify any issues

before they become serious problems, providing peace of mind to property owners. Additionally, the AMC

includes documentation of maintenance activities for safety audits and insurance purposes.

A fire extinguisher is a portable device designed to combat small fires quickly and effectively. It contains a fire-suppressing agent, such as water, foam, dry powder, or carbon dioxide, which is released when the extinguisher is activated. Fire extinguishers are classified into different types based on the kind of fires they can extinguish, such as those involving flammable liquids, electrical equipment, or ordinary combustibles. They are essential safety tools found in homes, offices, and public spaces to help prevent small fires from escalating. Proper training on how to use a fire extinguisher is crucial for effective response during a fire emergency.

The scope of work for fire extinguishers encompasses several critical activities to ensure their reliability and effectiveness in emergencies. It begins with regular visual inspections to confirm that extinguishers are accessible, properly mounted, and free from damage or corrosion.

Routine maintenance is performed according to manufacturer guidelines and local regulations, which includes checking pressure gauges and verifying that the extinguishing agent is within required limits. Functional tests, such as hydrostatic testing, assess the integrity of the extinguisher’s cylinder, while recharging is conducted after use or if the agent is low. Detailed documentation of all inspections, maintenance, and testing activities is maintained to ensure compliance with safety regulations

FIRE HYDRANT SYSTEM

- AMC

- DESCRIPTION

- SCOPE OF WORKS

What is an AMC?

An Annual Maintenance Contract is a service agreement between a property owner and a service provider for regular maintenance of fire hydrant systems.

Purpose of AMC:

The Annual Maintenance Contract (AMC) ensures that fire hydrants are always operational and ready to supply water in emergencies, helps identify and fix potential problems like leaks, rust, or blockages before they worsen, and ensures compliance with local regulations that mandate regular maintenance of fire safety equipment.

A fire hydrant system is a network of pipes and hydrants connected to a water supply, designed to provide firefighters with quick access to water during emergencies. Fire hydrants, usually located along streets, allow firefighters to connect hoses and draw water to extinguish fires. There are two main types: wet barrel hydrants, which have water in them at all times, and dry barrel hydrants, which are empty until needed to prevent freezing. Regular maintenance is essential to ensure that hydrants are functional and accessible, helping to protect lives and property by enabling rapid firefighting response.

The scope of work for a fire hydrant system includes the installation of hydrants and piping, conducting flow and pressure tests to ensure functionality, performing regular

inspections and maintenance to address any issues, keeping detailed records of all activities for compliance, providing training for personnel on proper use and emergency procedures, and coordinating with local fire services to ensure readiness in case of a fire emergency.

FOAM SUPRESSION SYSTEM

- AMC

- DESCRIPTION

What is an AMC?

An Annual Maintenance Contract is a service agreement between a property owner and a service provider for regular maintenance of foam supression system

Purpose of AMC:

The purpose of an Annual Maintenance Contract (AMC) for foam supression is to ensure they are regularly inspected and maintained for reliability and compliance with safety regulations. It helps identify any issues before they become serious problems, providing peace of mind to property owners. Additionally, the AMC includes documentation of maintenance activities for safety audits and insurance purposes.

Foam suppression is a fire protection method that uses a foam agent to extinguish fires, particularly those involving flammable liquids. The foam forms a blanket over the burning material, cutting off the oxygen supply and preventing the release of flammable vapors. This method is effective for Class B fires, which include liquids like gasoline, oil, and solvents. Foam suppression systems can be installed in fixed systems or used in portable extinguishers. They are commonly employed in industrial settings, aviation, and areas where flammable liquids are stored or processed.

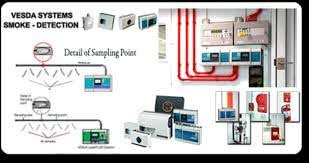

FIRE ALARM SYSTEM

- AMC

- DESCRIPTION

- SCOPE OF WORKS

What is an AMC?

An Annual Maintenance Contract is a service agreement between a property owner and a service provider for regular maintenance of foam supression system

Purpose of AMC:

The purpose of an Annual Maintenance Contract (AMC) for Fire alarm is to ensure they are regularly inspected and maintained for reliability and compliance with safety regulations. It helps identify any issues before they become serious problems, providing peace of mind to property owners. Additionally, the AMC includes documentation of maintenance activities for safety audits and insurance purposes.

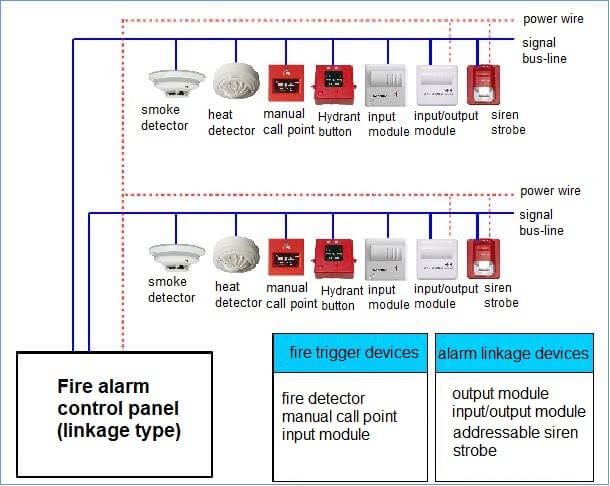

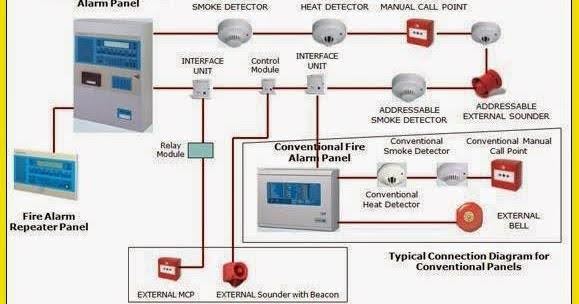

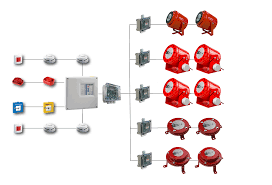

A fire alarm is a safety device designed to detect smoke or fire and alert people to danger. It usually consists of a sensor that detects smoke or heat, a loud siren or alarm that sounds when a fire is detected, and sometimes a visual signal like flashing lights. Fire alarms can be found in homes, offices, and public buildings, helping to ensure that everyone can evacuate safely in case of a fire. Regular testing and maintenance of fire alarms are important to ensure they work properly when needed.

The scope of fire alarms includes their use in various settings to enhance safety and protect lives and property. They are installed in homes, offices, schools, hospitals, and public buildings to detect fires early and alert occupants. Fire alarms can be part of larger fire safety systems that include sprinklers and emergency lighting. With advancements in technology, modern fire alarms can connect to smart home systems, allowing for remote monitoring and alerts via smartphones. Overall, the scope of fire alarms is crucial for preventing fire-related injuries and minimizing damage in case of a fire emergency.

POWDRED SUPPRESSION SYSTEM

- AMC

- DESCRIPTION

- SCOPE OF WORKS

What is an AMC?

An Annual Maintenance Contract is a service agreement between a property owner and a

service provider for regular maintenance of Powdred Suppression System

Purpose of AMC:

The purpose of an Annual Maintenance Contract (AMC) for Powdred Suppression System is to ensure they are regularly inspected and maintained for reliability and compliance with safety regulations. It helps identify any issues before they become serious problems, providing peace of mind to property owners. Additionally, the AMC includes documentation of maintenance activities for safety audits and insurance purposes.

DRY SPRINKLER POWDERED AEROSAL SUPRESSION SYSTEM

- AMC

- DESCRIPTION

- SCOPE OF WORKS

What is an AMC?

An Annual Maintenance Contract is a service agreement between a property owner and a service provider for regular maintenance of DRY SPRINKLER POWDERED AEROSAL SUPRESSION SYSTEM

Purpose of AMC:

The purpose of an Annual Maintenance Contract (AMC) for DRY SPRINKLER POWDERED AEROSAL SUPRESSION SYSTEM is to ensure they are regularly inspected and maintained for reliability and compliance with safety regulations. It helps identify any issues before they become serious problems, providing peace of mind to property owners. Additionally, the AMC includes documentation of maintenance activities for safety audits and insurance purposes.

A Dry Sprinkler Powdered Aerosol suppression system is a fire protection method that uses a fine powder aerosol to extinguish fires. Unlike traditional water-based sprinkler systems, this system releases a cloud of dry chemical agents when a fire is detected. The aerosol works by interrupting the chemical reactions that fuel the fire, effectively smothering it. This type of system is particularly useful in areas where water damage is a concern, such as in data centers, museums, or archives. It is designed to respond quickly to fires, providing an effective means of protection while minimizing damage to sensitive equipment and materials. Regular maintenance and testing are important to ensure the system functions properly when needed.

The scope of work for a Dry Sprinkler Powdered Aerosol (DSPA) suppression system typically

involves the installation, maintenance, and testing of the aerosol generators, ensuring they are

properly powered and functional. This includes conducting inspections, functional tests, and

sensitivity tests to verify the system’s effectiveness in suppressing fires in confined or enclosed

spaces. The DSPA system is designed to be deployed quickly by firefighters, reducing the

intensity of fires and minimizing water damage. Additionally, the scope includes training

personnel on the proper use of the DSPA units, ensuring compliance with safety regulations,

and maintaining accurate records of inspections and maintenance activities. Overall, the goal

is to enhance fire safety and protection in areas where traditional water-based systems may not

be suitable..

GAS SUPRESSION SYSTEM - NOVEC

- AMC

- DESCRIPTION

- SCOPE OF WORKS

What is an AMC?

An Annual Maintenance Contract is a service agreement between a property owner and a service provider for regular maintenance of GAS SUPRESSION SYSTEM-NOVEC

Purpose of AMC:

The purpose of an Annual Maintenance Contract (AMC) for GAS SUPRESSION SYSTEM-NOVEC is to ensure they are regularly inspected and maintained for reliability and compliance with safety regulations. It helps identify any issues before they become serious problems, providing peace of mind to property owners. Additionally, the AMC includes documentation of maintenance activities for safety audits and insurance purposes.

The Novec gas suppression system utilizes 3M™ Novec™ 1230 fluid, a clean agent that effectively extinguishes fires without leaving residue or causing damage to sensitive equipment. This system is designed to be environmentally friendly and safe for occupied spaces, making it ideal for protecting critical assets in data centers, museums, and healthcare facilities. The Novec 1230 fluid works by absorbing heat from the fire, thereby interrupting the combustion process. It has a low global warming potential and does not deplete the ozone layer, making it a sustainable choice for fire protection. The system includes components such as detectors, control units, agent storage cylinders, and discharge nozzles, all of which work together to provide rapid and effective fire suppression. Additionally, Novec 1230 can be used as a substitute for halon systems, offering comparable protection with only minor adjustments needed for existing infrastructure.

The scope of work for a Novec gas suppression system encompasses the design, installation, testing, and maintenance of the fire suppression system utilizing 3M™ Novec™ 1230 fluid. This includes conducting a thorough risk assessment to determine the specific needs of the facility and identifying areas that require protection. The installation process involves setting up the necessary components, such as storage cylinders, piping, nozzles, and detection systems, ensuring compliance with relevant fire safety codes and standards. Following installation, the system undergoes rigorous testing to verify its functionality and effectiveness in extinguishing fires. Ongoing maintenance is also a critical aspect of the scope, which includes regular inspections, system recharges, and performance testing to ensure reliability and readiness in the event of a fire. Additionally, training for facility personnel on the operation and safety protocols associated with the Novec suppression system is provided to ensure preparedness and effective response in case of an emergency. Overall, the goal is to create a comprehensive fire protection solution that safeguards valuable assets while minimizing environmental impact.

GAS SUPRESSION SYSTEM-FM 200

- AMC

- DESCRIPTION

- SCOPE OF WORKS

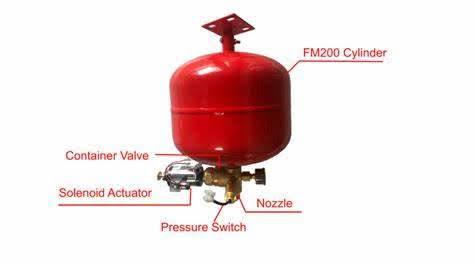

What is an AMC?

An Annual Maintenance Contract is a service agreement between a property owner and a service provider for regular maintenance of GAS SUPRESSION SYSTEM-FM200

Purpose of AMC:

The purpose of an Annual Maintenance Contract (AMC) for GAS SUPRESSION SYSTEM- FM200 is to ensure they are regularly inspected and maintained for reliability and compliance with safety regulations. It helps identify any issues before they become serious problems, providing peace of mind to property owners. Additionally, the AMC includes documentation of maintenance activities for safety audits and insurance purposes.

The FM-200 gas suppression system is a fire protection solution that uses HFC-227ea, a clean agent known for its effectiveness in extinguishing fires without leaving any residue. This system is designed to protect sensitive environments, such as data centers, telecommunications facilities, and museums, where traditional water-based fire suppression methods could cause damage to equipment or valuable items. FM-200 works by rapidly absorbing heat and interrupting the combustion process, effectively extinguishing the fire within seconds. It is safe for occupied spaces, as it has a low toxicity level and does not pose a risk to human health when used properly. Additionally, FM-200 has a low global warming potential, making it a more environmentally friendly option compared to some other chemical agents. The system typically includes components such as storage cylinders, piping, nozzles, and detection systems, all designed to work together to provide reliable and efficient fire protection.

The scope of work for an FM-200 gas suppression system encompasses a comprehensive approach to fire protection, beginning with a detailed assessment of the facility to identify areas requiring coverage, such as data centers or sensitive equipment rooms. Following this, a tailored design plan is developed, outlining the layout of the system, including the placement of storage cylinders, piping, nozzles, and detection devices, ensuring compliance with relevant fire safety standards. The installation phase involves the professional setup of all components, ensuring proper integration and functionality. Once installed, the system undergoes rigorous testing to verify its operational effectiveness and readiness for emergency situations. Ongoing maintenance is a critical aspect of the scope, involving regular inspections, refills of FM-200 cylinders, and performance checks to ensure reliability. Additionally, training is provided for facility personnel on the system’s operation and safety protocols, ensuring preparedness in the event of a fire.

GAS SUPRESSION SYSTEM- INRGEN

- AMC

- DESCRIPTION

- SCOPE OF WORKS

What is an AMC?

An Annual Maintenance Contract is a service agreement between a property owner and a service provider for regular maintenance of GAS SUPRESSION SYSTEM- INRGEN

Purpose of AMC:

The purpose of an Annual Maintenance Contract (AMC) for GAS SUPRESSION SYSTEM- INRGEN is to ensure they are regularly inspected and maintained for reliability and compliance with safety regulations. It helps identify any issues before they become serious problems, providing peace of mind to property owners. Additionally, the AMC includes documentation of maintenance activities for safety audits and insurance purposes.

The Inergen gas suppression system is a fire protection solution that uses a blend of naturally occurring gases—primarily nitrogen, argon, and carbon dioxide—to extinguish fires. It works by reducing the oxygen concentration in the air to a level that is insufficient to support combustion, effectively suffocating the fire. Inergen is safe for occupied spaces, as it does not pose health risks to humans at the concentrations used for fire suppression. This system is particularly suitable for protecting sensitive environments, such as data centers, archives, and museums, where traditional water-based systems could cause damage. Inergen is also environmentally friendly, as it does not contribute to ozone depletion or global warming

The scope of work for an Inergen gas suppression system includes several key phases: assessment, design, installation, testing, and maintenance. Initially, a thorough assessment of the facility is conducted to identify areas that require fire protection, such as data centers or sensitive equipment rooms. Based on this assessment, a customized design plan is created, detailing the layout of the system, including the placement of storage cylinders, piping, and nozzles, while ensuring compliance with fire safety regulations. The installation phase involves the professional setup of all components, ensuring they are properly integrated and functional. After installation, the system undergoes rigorous testing to confirm its effectiveness in extinguishing fires.

GAS SUPRESSION SYSTEM- FK512

- AMC

- DESCRIPTION

- SCOPE OF WORKS

What is an AMC?

An Annual Maintenance Contract is a service agreement between a property owner and a

service provider for regular maintenance of GAS SUPRESSION SYSTEM- FK512

Purpose of AMC:

The purpose of an Annual Maintenance Contract (AMC) for GAS SUPRESSION SYSTEM- FK512 is to ensure they are regularly inspected and maintained for reliability and compliance with safety regulations. It helps identify any issues before they become serious problems, providing peace of mind to property owners. Additionally, the AMC includes documentation of maintenance activities for safety audits and insurance purposes.

The FK-512 gas suppression system uses FK-5-1-12, a clean agent designed to extinguish fires quickly and effectively without leaving any residue. This system is ideal for protecting sensitive areas like data centers, server rooms, and museums, where traditional water-based fire suppression could damage valuable equipment or items. FK-512 works by cooling the fire and interrupting the combustion process, allowing it to extinguish flames within seconds. It is safe for occupied spaces, as it has low toxicity and poses minimal risk to human health. Additionally, FK-5-1-12 has a low global warming potential, making it an environmentally friendly option. The system includes components such as storage cylinders, piping, and nozzles, all working together to provide reliable fire protection in critical environments.

The scope of work for the FK-512 gas suppression system includes several essential phases: assessment, design, installation, testing, and maintenance. First, a thorough assessment of the facility is conducted to identify areas that need fire protection, such as data centers or sensitive equipment rooms. Based on this assessment, a customized design plan is created, detailing the layout of the system, including the placement of storage cylinders, piping, and nozzles, while ensuring compliance with fire safety regulations. The installation phase involves the professional setup of all components, ensuring they are properly integrated and functional. After installation, the system undergoes rigorous testing to confirm its effectiveness in extinguishing fires. Ongoing maintenance is crucial and includes regular inspections, refills of FK-5-1-12 gas cylinders, and performance checks to ensure the system remains reliable.

PUBLIC ADDRESS SYSTEM

- AMC

- DESCRIPTION

- SCOPE OF WORKS

What is an AMC?

An Annual Maintenance Contract is a service agreement between a property owner and a

service provider for regular maintenance of Public Address System

Purpose of AMC:

The purpose of an Annual Maintenance Contract (AMC) for Public Address System is to ensure they are regularly inspected and maintained for reliability and compliance with safety regulations. It helps identify any issues before they become serious problems, providing peace of mind to property owners. Additionally, the AMC includes documentation of maintenance activities for safety audits and insurance purposes.

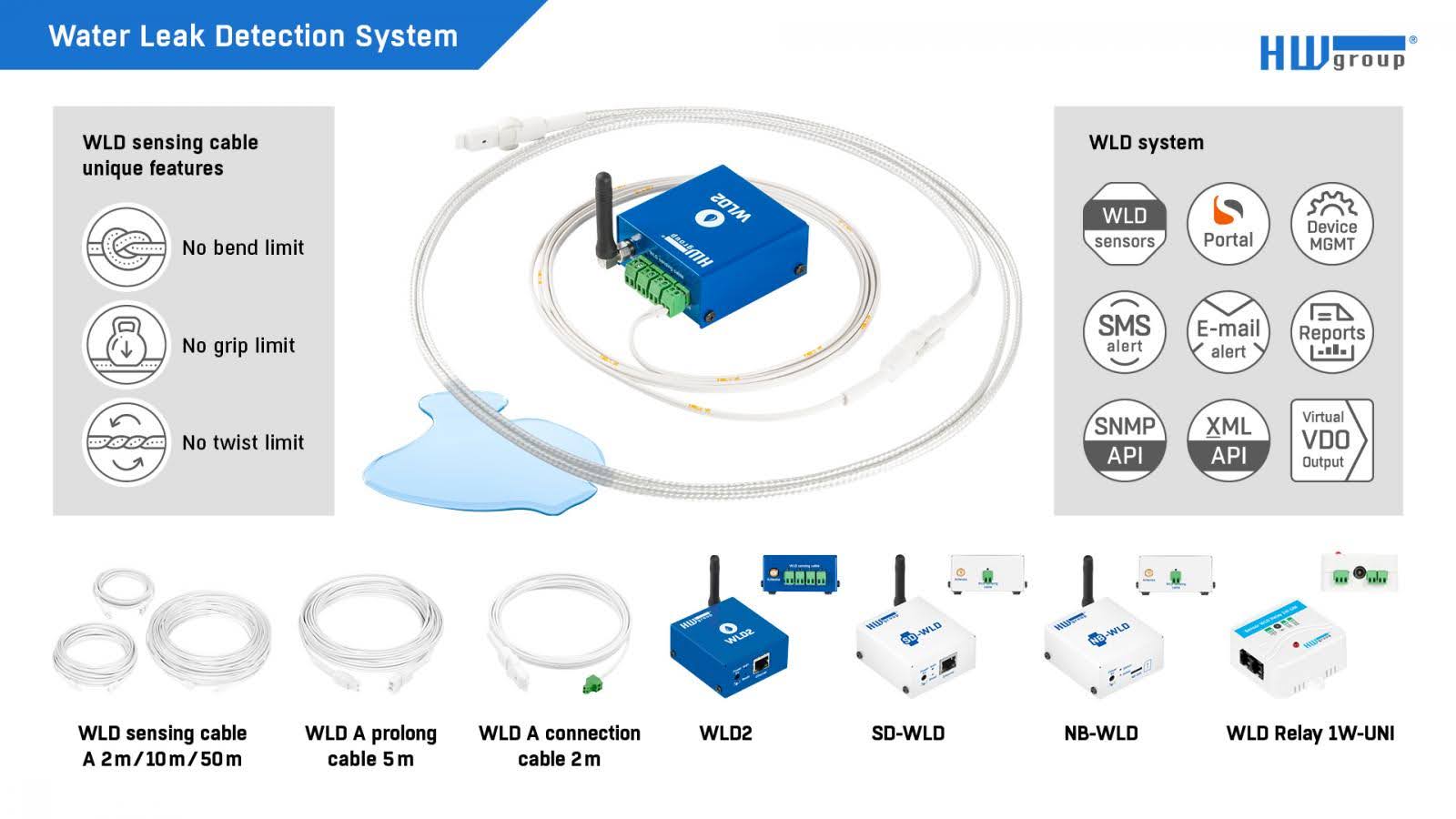

Water leak detection is a system designed to identify and locate leaks in plumbing, roofs, or other structures before they cause significant damage. These systems use various technologies, such as sensors, acoustic devices, or moisture meters, to monitor areas for signs of water presence. When a leak is detected, the system alerts users through alarms or notifications, allowing for quick action to be taken to address the issue. Water leak detection is essential for protecting buildings, reducing repair costs, and preventing water damage, mold growth, and other related problems. Overall, it helps maintain the integrity of structures and ensures a safe and dry environment

The scope of work for a water leak detection system includes several key phases: assessment, design, installation, testing, and maintenance. First, a thorough assessment of the facility is conducted to identify areas at risk for leaks, such as basements, roofs, and plumbing systems. Based on this assessment, a customized design plan is created, detailing the placement of sensors and monitoring equipment to ensure comprehensive coverage. The installation phase involves setting up all components, including sensors, alarms, and control panels, ensuring they are properly connected and configured. After installation, the system undergoes testing to verify its functionality and responsiveness to leaks.Ongoing maintenance is also part of the scope, which includes regular inspections, calibrations, and repairs to ensure the system operates effectively over time

RODENT REPELLENT SYSTEM

- AMC

- DESCRIPTION

- SCOPE OF WORKS

What is an AMC?

An Annual Maintenance Contract is a service agreement between a property owner and a

service provider for regular maintenance of RODENT REPELLENT System

Purpose of AMC:

The purpose of an Annual Maintenance Contract (AMC) for RODENT REPELLENT System is to ensure they are regularly inspected and maintained for reliability and compliance with safety regulations. It helps identify any issues before they become serious problems, providing peace of mind to property owners. Additionally, the AMC includes documentation of maintenance activities for safety audits and insurance purposes.

Rodent repellent is a product or system designed to deter rodents, such as mice and rats, from entering or nesting in a specific area. These repellents can come in various forms, including sprays, granules, ultrasonic devices, and natural substances like peppermint oil. They work by emitting scents, sounds, or vibrations that are unpleasant to rodents, encouraging them to stay away. Rodent repellents are commonly used in homes, gardens, and commercial spaces to prevent infestations and protect property from damage caused by these pests. Overall, they provide a proactive approach to keeping rodents at bay without the use of harmful chemicals or traps.

The scope of work for a rodent repellent system includes several key steps: assessment, selection, application, monitoring, and maintenance. First, a thorough assessment of the area is conducted to identify potential entry points and nesting sites for rodents. Based on this assessment, appropriate rodent repellent products or systems are selected, which may include sprays, granules, or ultrasonic devices. The application phase involves strategically placing or applying the chosen repellents in areas where rodent activity is likely. After application, monitoring is essential to evaluate the effectiveness of the repellent and to check for any signs of rodent activity. Ongoing maintenance may include reapplication of repellents and regular inspections to ensure continued effectiveness. Overall, the goal is to create a rodent-free environment while minimizing the risk of infestations and protecting property.

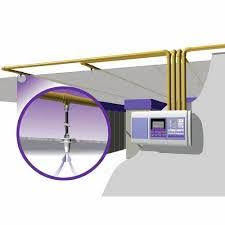

VESDA SUPPRESSION SYSTEM

- AMC

- DESCRIPTION

- SCOPE OF WORKS

What is an AMC?

An Annual Maintenance Contract is a service agreement between a property owner and a

service provider for regular maintenance of VESDA SUPPRESSION SYSTEM

Purpose of AMC:

The purpose of an Annual Maintenance Contract (AMC) for VESDA SUPPRESSION SYSTEM is to ensure they are regularly inspected and maintained for reliability and compliance with safety regulations. It helps identify any issues before they become serious problems, providing peace of mind to property owners. Additionally, the AMC includes documentation of maintenance activities for safety audits and insurance purposes.

The VESDA (Very Early Smoke Detection Apparatus) system is a highly sensitive smoke detection system designed to identify smoke at its earliest stages, often before a fire becomes visible. It works by continuously drawing air from the protected area through a network of pipes to a central detection unit, where advanced sensors analyze the air for smoke particles. If smoke is detected, the system can trigger alarms and alert personnel, allowing for quick response to potential fire hazards. VESDA systems are commonly used in critical environments such as data centers, museums, and industrial facilities, where early detection is crucial for safety and protection of valuable assets. Overall, VESDA provides a proactive approach to fire safety by ensuring that even the smallest signs of smoke are detected promptly.

The scope of work for a VESDA (Very Early Smoke Detection Apparatus) system includes several key phases: assessment, design, installation, testing, and maintenance. First, a thorough assessment of the facility is conducted to identify areas that require smoke detection, particularly in high-risk environments like data centers or archives. Based on this assessment, a customized design plan is created, detailing the layout of the system, including the placement of sampling pipes and detection units to ensure optimal coverage. The installation phase involves setting up all components, ensuring they are properly connected and configured. After installation, the system undergoes rigorous testing to verify its functionality and sensitivity in detecting smoke. Ongoing maintenance is also part of the scope, which includes regular inspections, cleaning of sensors, and performance checks to ensure the system remains reliable over time

GAS DETECTION SYSTEM

Scope of Works

- Installation

- Calibration

- Maintenance

- Integration

- Training

- Documentation

Setting up the gas detection system in designated areas, ensuring proper placement of sensors for optimal detection.

Regular calibration of sensors to maintain accuracy and reliability in detecting gas concentrations.

Ongoing maintenance to ensure the system operates effectively, including routine checks and repairs as needed.

Connecting the gas detection system with existing safety protocols and alarm systems to enhance overall safety measures.

Providing training for personnel on how to respond to alarms and operate the gas detection system effectively.

Maintaining records of installation, calibration, maintenance, and training activities for compliance and safety audits.

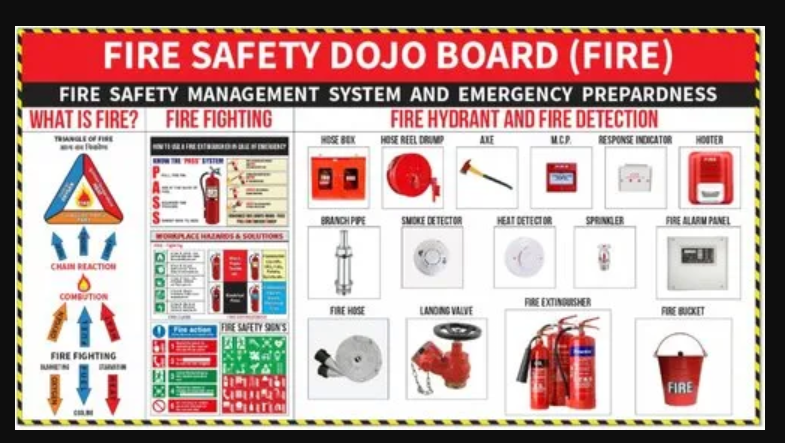

Dojo Board

Welcome to the Fire Safety Engineering Dojo Board! This is your go-to space for all updates, resources, and collaboration related to our fire safety projects. Here, you can find important announcements, project statuses, safety tips, and training materials. Let’s work together to ensure the highest standards of fire safety and protection for our clients. If you have any questions or need assistance, feel free to reach out!

1. Fire Safety Guidelines

Overview: Start with a brief introduction about the importance of fire safety in the dojo. Emphasize that being prepared can save lives and prevent injuries. Key Points: Always keep exits clear and accessible. Do not block fire extinguishers or alarms. Avoid using flammable materials near heat sources. Ensure that all electrical equipment is in good condition and not overloaded.

2. Emergency Evacuation Plan

Visual Maps: Create a clear, easy-to-read map of the dojo layout, marking all exits, stairwells, and assembly points outside the building. Instructions: Include step-by-step instructions on how to evacuate safely: Remain calm and do not run. Follow the designated evacuation routes. Assist others, especially those who may need help (e.g., children, elderly, or disabled individuals). Do not use elevators during a fire.

3. Fire Extinguisher Locations

Visual Indicators: Use signs or symbols to indicate where fire extinguishers are located throughout the dojo. Usage Instructions: Provide a brief guide on how to use a fire extinguisher (PASS method): Pull the pin. Aim low at the base of the fire. Squeeze the handle. Sweep side to side.

4. Fire Safety Procedures

In Case of Fire: Outline what to do if a fire is detected: Activate the nearest fire alarm. Evacuate immediately using the designated routes. Call 911 or the local emergency number once safe. If Trapped: Provide instructions for those who may be trapped: Stay low to avoid smoke inhalation. Seal doors with clothing or towels to prevent smoke from entering. Signal for help from a window if possible.

5. Common Fire Hazards

List of Hazards: Identify specific fire hazards in the dojo environment: Flammable materials (e.g., mats, uniforms, cleaning supplies). Electrical equipment (e.g., lights, sound systems). Cooking equipment (if applicable). Prevention Tips: Offer tips on how to mitigate these hazards, such as proper storage of flammable materials and regular maintenance of electrical equipment.

6. Emergency Contacts

Important Numbers: List emergency contact numbers prominently: Local fire department: [insert number] Emergency services: 911 Dojo emergency contact person: [insert name and number] Communication Plan: Explain how information will be communicated during an emergency (e.g., loudspeaker, text alerts).

7. Visual Aids

Infographics: Use infographics to illustrate fire safety tips, evacuation routes, and the PASS method for using a fire extinguisher. Posters: Create posters that can be displayed around the dojo, reinforcing key fire safety messages.

8. Interactive Elements

Quizzes: Create a short quiz on fire safety knowledge that students can take to reinforce what they’ve learned. Checklists: Provide a fire safety checklist that students can review at the beginning of each class to ensure they are aware of safety protocols.

9. Regular Updates

Review Schedule: Establish a schedule for reviewing and updating fire safety information, ensuring it remains current and relevant. Training Sessions: Organize regular fire safety training sessions for students and staff to practice evacuation procedures and the use of fire extinguishers.

10. Dojo-Specific Tips

Training Safety: Discuss how to safely handle equipment during training to prevent accidents that could lead to fire hazards. Personal Safety: Encourage students to wear appropriate clothing and gear that is less likely to catch fire.

11. Fire Drill Schedule

Drill Dates: Clearly outline when fire drills will take place, ensuring everyone knows the schedule. Drill Procedures: Explain what to expect during a drill and the importance of treating it as a real emergency.

12. Community Resources

Local Workshops: Share information about local fire safety workshops or community events focused on fire prevention. Online Resources: Provide links to reputable fire safety organizations or websites for further reading.

Conclusion

By incorporating these detailed elements into your dojo board, you will create a comprehensive fire safety resource.